Our News ENERTECH News

-

Enertech International Workshop One Team-One Win

The management of Enertech Int held a corporate climbing on Mt. Woraksan to reach the 1000m peak. This climbing was dedicated to the beginning of construction works of the second production site of Enertech and starting of a new era in Company history.The booming demand will allow to increase production volumes and at the same time it is a challenge for the team.So, with Company growth, we plan to hire more than 100 employees in 2023.The Company offers attractive working terms and conditions and various benefits, including additional compensation for employees from other cities.United Enertech team succeeds in achieving business goals as lofty as conquering the top of the Mountain. Join us now!관리자

-

Enertech invests KRW 35 billion in factory expansion in 2023

Enertech International (Enertech / ETI) will invest KRW 35 billion in the expansion of secondary battery plants. Through expansion, the production scale will be more than tripled.Founded in 2001, Enertech produces secondary batteries for electric vehicles and energy storage systems (ESS). The current production scale is 150MWh. Enertech will expand its factory to close the technology gap with the three major domestic battery companies and lay the foundation for growth. Investment is to expand its production capacity to 500MWh next year.The expansion line produces more than 3 million 60Ah battery cells per year. It has a nickel-cobalt-manganese ratio of 8:1:1. Both secondary batteries and ESS can be applied, and test discussions are underway with customers. Enertech expects to be able to acquire new customers in Korea and the United States through the expansion.Enertech also invests in building for module and pack assembly automation lines. Three modular automated assembly lines and one pack assembly line will be put into operation in May next year. Enertech aims to enter the module and pack assembly business for electric vehicles after 2024 through the construction of an automation line.Enertech has also developed special-purpose lithium iron phosphate (LFP) cells and hybrid vehicle (HEV) cells, and have acquired customers in the development stage.Enertech official said, "ETI is aiming to supply the products produced by the new module and pack assembly line to domestic and foreign automakers," adding, "ETI will continue to invest in a virtuous cycle factory operation structure centered on the cells produced through expansion."Enertech International researcher examines batteries at the research center관리자

-

Accelerating EV battery development

Enertech plans to introduce a new model, the VDA cell, in the second half of 2022.The VDA model provides a useful size for EV batteries by minimizing space consumption when configured as a pack with low and long battery cell type.The cell development is scheduled to be completed in the second half of 2022, and the production of this VDA model is the reason for the plant jointly established by Renera-Enertech, a Russian subsidiary, and Rosatom, Russia.Enertech, which has been recognized for its safety and quality, is already carrying out projects with major customers with the goal of commercializing electric vehicles in Russia immediately following the completion of the factory establishment.Enertech's Existing heavy duty truck, two-wheeled vehicles, and bus customers and new models are also under review, and plant expansion is already being considered in Korea.admin

-

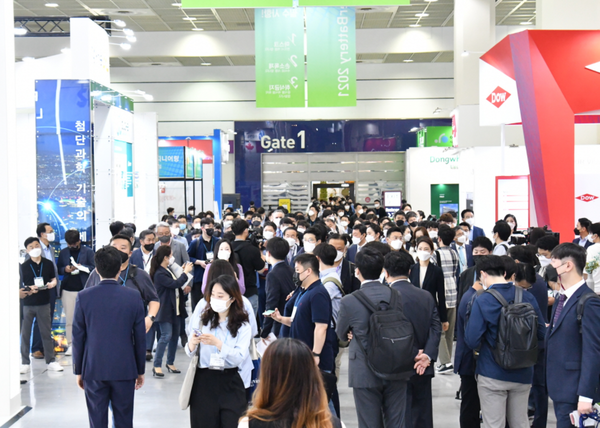

Inter Battery 2022 !

‘InterBattery 2022’ hosted by the Ministry of Trade, Industry and Energy and hosted by the Korea Battery Industry Association and COEX was held from March 17 to 19 at COEX Hall A in Samseong-dong, Seoul.Interbattery is the only battery-specialized exhibition in Korea, with secondary battery manufacturers participating, and 250 domestic and foreign companies leading the battery market such as anode materials and electrolytes participated. .In 'xEV TREND KOREA 2022' (March 17-19), which was held simultaneously with this event, a large number of domestic electric vehicle brands such as Hyundai Motor, Kia Motors, and Volvo participated, and various EV models that were recently released or planned to be released in the future were exhibited, providing a variety of attractions. provided.Lee Myung-gyu, head of the Korea Battery Business Association, said, “Despite the Corona situation, the scale is 1.5 times larger than the previous year, attracting attention from the industry, so we prepared the latest innovative battery trends in one place. We will be able to confirm the competitiveness of domestic battery companies that are attracting attention in this industry.”admin

-

Hansong Neotech, contract deal with Enertech

Shinhwa IT, a secondary battery subsidiary of Hansong Neotech, has successfully signed a long-term supply contract for high-performance secondary battery materials with a global electric vehicle battery manufacturer.Shinhwa IT has recently signed strategic MOUs with supply negotiations with US 'Solid Energy System', 'Enovix', and 'Zhongxin Guan Menggu (MGL)' of China.Shinhwa IT announced on the 20th that it has signed a long-term supply contract with Enertech International (Enertech), a global electric vehicle battery manufacturer, to supply an initial supply worth 6.2 billion won. This contract will be supplied as a customized mass production model through Spec-in. The contract period is 3 years. Enertech, established in 2001, will commercialize 80% nickel NCM batteries and supply them to American automakers' delivery vans. Enertech recently agreed to supply batteries for 100,000 electric vehicles to Avotor, Russia's largest automaker, and is also pursuing the construction of an additional plant in Russia due to an increase in new orders.Last year, Enertech was acquired by RENERA LLC, a subsidiary of Russia's state-owned company Rosatom, the world's No. Enertech's Russian plant is adjacent to Europe, so it plans to build a battery supply chain to strengthen its penetration into the global electric vehicle market.Shinhwa IT recently decided to expand secondary battery material manufacturing plants and production facilities in preparation for an increase in orders from a number of global customers, and aims to complete it by the third quarter of this year. After completion, Shinhwa IT's production capacity for high-performance lead tabs will be expanded five times, enabling it to respond to the high-spec battery market where demand is rapidly increasing.An official from Hansong Neotech said, “Shinhwa IT is accelerating the expansion of the secondary battery material business by signing strategic alliances with global next-generation battery companies and negotiating supply agreements.” “Through this long-term supply contract with Enertech, Russia It is expected to increase the supply volume in the future as it will prepare a foothold to enter the European and European markets.”He continued, “In addition, we are discussing technology development with global all-solid-state battery companies, and the demand for high-performance and high-capacity lead taps is expected to surge due to the increase in battery capacity and performance improvement. And we are responding quickly, such as by expanding production facilities.”[www.theguru.co.kr/news/article.html?no=30509]admin

-

Enertech to apply 'silicone anode material' for the first time to electric bike batteries

Enertech International and Enervate, a battery-based startup in the United States, are pushing to install a battery based on a silicon anode material in electric motorbikes. Silicon anode material is considered as a new next-generation battery material that speeds up battery charging and increases energy capacity. Enertech plans to supply batteries with silicon anode materials from next year.According to the industry on the 14th, Enertech International plans to supply batteries with silicon anode material to Italian motorbike makers next year.Silicon anode material shortens battery charging time and increases energy density. It is attracting attention as a next-generation battery material because its energy density is 10 times higher than that of existing graphite-based anode materials. According to the industry, the silicon anode material market is expected to grow to 5.5 trillion won in 2025.The silicon anode material is supplied by Enervate of the US, and the battery is manufactured by Enertech. Enertech plans to apply Enervate silicon anode material to high-nickel 'NCM (nickel, cobalt, manganese)' batteries to be installed in electric bikes scheduled to be released in the second half of next year.An Enertech official said, "Battery with a silicon anode material will be able to charge as fast as the refueling time of an internal combustion engine vehicle and realize high energy density."This is the first time that Enertech has applied a silicon anode material to an NCM battery. Although silicon anode material enhances battery performance, it is known to be supplied to the premium electric motor market because it can increase the battery manufacturing cost.Enertech plans to expand the application of silicon anode material to premium electric vehicles as well as electric bikes. LG Energy Solutions applied silicon anode material to the premium electric vehicle brand Taycan, which was first launched by Porsche in 2019.Deok-geun Oh, CEO of Enertech, said, "We will speed up battery development to meet customer needs by combining Enertech's NCM battery manufacturing technology and Enervate's silicon anode material technology."Enervate CEO Robert Lango said, "Silicone anode material will be able to improve battery fast charging and energy density."[www.etnews.com/20210614000102]admin

-

Enertech and Ewha Electric signed an agreement for a joint factory

Enertech International CEO Oh Deok-geun (left) and Ewha Electric Vice President Shim Bo-geun took a commemorative photo after signing a business agreement to establish a battery pack joint factory. [Source: Enertech]<Enertech International CEO Oh Deok-geun (left) and Ewha Electric Vice President Shim Bo-geon took a commemorative photo after signing a business agreement to establish a battery pack joint factory. [Source: Enertech]>Enertech International and Ewha Electric are producing batteries for uninterruptible power supply (UPS). In order to target the Middle East nuclear power plant market, a domestic battery maker and a power equipment maker have joined hands. It is expected to target the domestic and foreign nuclear power plant market.Enertech and Ewha Electric announced on the 6th that they had exchanged a memorandum of understanding (MOU) for the establishment of a battery pack joint venture in the presence of Enertech CEO Oh Deok-geun and Ewha Electric Vice President Shim Jeong-jeong.The two companies decided to build a UPS battery pack factory in Gyeonggi-do with the goal of establishing a joint venture (JV) within this year. Specific UPS production capacity and customer companies have been decided through discussion later. A UPS is a type of medium-to-large energy storage system (ESS), which is an emergency power supply device that stores power and takes it out when needed.Enertech entered into battery manufacturing in 2001 and has been recognized by domestic and foreign companies for its solid technology and production facilities. It supplies batteries for electric vehicles to US and Russian companies. In particular, the largest shareholder is the world's largest Russian nuclear power plant company, pursuing ESS and electric vehicle battery businesses.Ewha Electric is promoting various overseas projects as the demand for domestic UPS products is increasing. In a situation where they are looking for a stable battery supplier, they are targeting the UPS market in cooperation with Enertech.An official from the two companies said, "With a battery joint venture between specialized domestic manufacturers, we will seek new opportunities not only in the domestic market but also in overseas markets such as Russia and the Middle East."[www.etnews.com/20210606000030]admin

-

Enertech challenges to commercialize LFP batteries for electric vehicles

Domestic battery specialists have joined forces to develop lithium iron phosphate (LFP) batteries for electric vehicles, drawing attention. LFP is evaluated as a battery with good safety and low price. However, in the meantime, there are few places that manufacture it in Korea, and it has only been used for special purposes. However, interest in LFP batteries has increased as battery cost reduction has become a hot topic in the electric vehicle era.According to the industry on the 24th, Energy Materials and Enertech International started to develop LFP batteries with the goal of mounting electric vehicle batteries. Energy Materials is in charge of the LFP cathode material, and Enertech International plans to make a finished battery for electric vehicles based on the cathode material.LFP was mainly driven by Chinese battery makers. However, LFP batteries have recently been attracting attention again. In order to advance the era of electric vehicles, the price of batteries must also be lowered, and LFP is emerging as a suitable battery for the popularization of electric vehicles.In addition, in the case of LFMP batteries with manganese added to LFP, it is known that the battery performance can be strengthened while maintaining safety at a low price, so the growth potential of the LFP battery market is increasing.Energy Materials and Enertech International are currently in the development stage, so it remains to be seen whether the final commercialization will be made, but expectations are high on the outcome as it is a collaboration between the only LFP cathode material company in Korea and a professional company with a history of supplying batteries to electric vehicles and electric buses. there is.An Energy Materials official said, "We are promoting the development of cathode materials that compensate for product performance problems while maintaining the low price and safety of LFP batteries.[www.etnews.com/20210524000100]admin

-

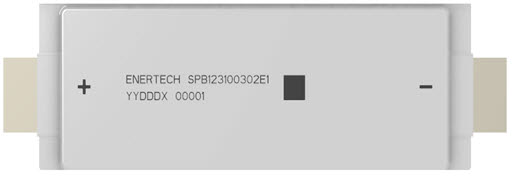

New Enertech battery of NCM 811

1. Gen4 EV Specification 1) Gen 4 EV cell increased the capacity by 17% (5Ah) from the existing Gen 3 EV cell by applying Nickel-rich(NCM811) cathode active material. - Gen3 EV : 25Ah - Gen4 EV : 30Ah 2) Operation at Low Temp and high output characteristics are equivalent to Gen 3 EV cell. 2. Gen4 EV development plan 1) Gen4 EV cell development is to be completed and will be ready for PO from Q2 in 2021admin

-

Enertech battery on Incheon Monorail

Korea's longest urban tourist monorail has started running again.The Monorail with 14.4 Km/h of speed was built with the cells & sub-packs supplied by Enertech International, Inc. based on pure domestic technology and praised for its outstanding safety features. The battery, capacity range from 6 Kwh to 27 Kwh, has been selected as a suitable solution for the monorail business that was likely to be discontinued due to safety issues before.The solution of Monorail in Incheon proved its quality of the battery and Enertech will be playing a key role starting from Incheon city to nationwide as the business grows.admin